Smart Factory (AU4956)

Limited to: AZ, CA, HI, MN, NV, OR, WA, WI

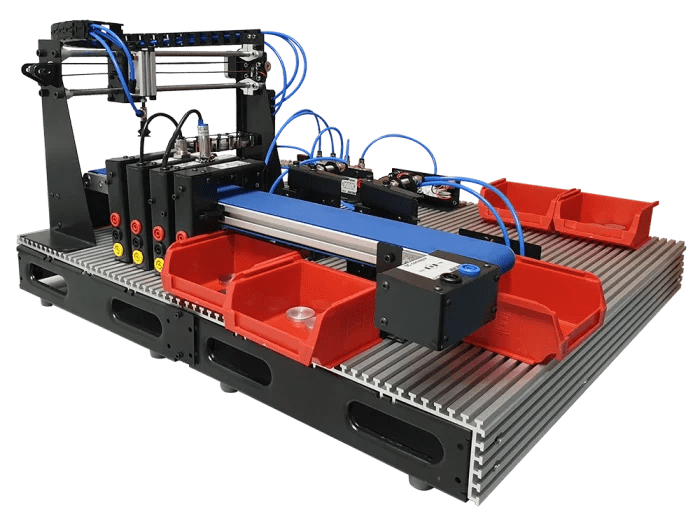

The Smart Factory offers a hands-on introduction to modern manufacturing processes, giving students practical experience with conveyor systems, sensing technology, pneumatic pick-and-place devices, DC motor drives, and stepper motor drives. Using colored plastic and other material discs, the system simulates an automated sorting process: a conveyor moves parts into the factory, where programmed sensors identify and direct them into various rejection bins. Some parts are removed using a vacuum suction device, while a stepper motor-driven gantry sorts them into color-matched containers.

Compact and self-contained, the Smart Factory can be easily stored in one of our standard trays. It integrates seamlessly with Siemens S7 PLC and HMI controls, and is compatible with the AllCode robot arm production cell for expanded Industry 4.0 applications.

Features

- Fully self-contained smart factory for training in automation and manufacturing

- Includes conveyor system, pneumatic pick-and-place device, and gantry sorting system

- Color and material sensing with programmable sorting into multiple bins

- DC motor and stepper motor drives for realistic motion control

- Works with Siemens S7 PLC and HMI (software available upon request)

- Easily integrates with AllCode robot arm production cell for Industry 4.0 scenarios

- Compact design with standard tray storage

- Real-world automation processes including vacuum pick-and-place and multi-axis sorting